Announcement

We don't sale this chemicals, here ONLY for check the basic information of this chemical compound.

Mar. 31th 2025

Light stabilizer 770 (HALS 770), also known as light stabilizer ZX-70, has a molecular formula of C28H50N2O4 and a molecular weight of 478.7087. It is mainly used as a highly efficient hindered amine light stabilizer and is suitable for polypropylene, polyethylene, ABS resin, polyurethane, etc. 770 belongs to low molecular weight hindered amine light stabilizers (HALS). It can prevent the degradation of polypropylene, polystyrene, ABS, polyurethane, engineering plastics, and polyamide caused by ultraviolet radiation. It provides excellent long-term stability through a free radical capture mechanism similar to hindered phenols. Very effective for products with high specific surface area, such as film and magnetic tape.

Case customer

|

|

|

|

Tinuvin 770, also known as Light Stabilizer 770, CAS 52829-07-9, with molecular formula C28H52N2O4, usually appears as a white or light yellow powder solid in appearance. Its particles are delicate and easy to mix with polymer materials, ensuring uniform distribution during processing and use, and achieving maximum light stabilization effect. Light Stabilizer 770 is usually soluble in organic solvents such as ethanol, acetone, etc., which makes it convenient to add the light stabilizer 770 to the reaction system when preparing polymer materials. However, its solubility in water is relatively low, which helps to maintain its stability in polymer matrices in applications. The density is moderate, which allows for precise control of its addition amount in polymer materials, thereby avoiding performance issues caused by excess or insufficient. As an important chemical additive, it is widely used in various polymer materials to provide excellent photostability and prevent degradation caused by light exposure. It has diverse and comprehensive functions, which can prevent UV damage to polymer materials, as well as good stability and compatibility; At the same time, its environmental and safety characteristics have also made it widely used in various fields. With the continuous progress of technology and the increasing demand for material performance, the light stabilizer 770 will undoubtedly play a more important role in the future. In the field of chemistry, as an important light stabilizer, its decomposition process has attracted much attention. After in-depth research and experimental verification, we found that Light Stabilizer 770 can decompose into piperidone under specific conditions. This discovery not only enriches our understanding of its chemical properties, but also provides a new pathway for the synthesis of piperidone.

|

|

|

|

Chemical Formula |

C28H52N2O4 |

|

Exact Mass |

480 |

|

Molecular Weight |

481 |

|

m/z |

480 (100.0%), 481 (30.3%), 482 (2.7%), 482 (1.7%) |

|

Elemental Analysis |

C, 69.96; H, 10.90; N, 5.83; O, 13.31 |

Tinuvin 770, as an efficient hindered amine light stabilizer, plays a crucial role in modern chemical and plastic industries. Its diverse and unique functions provide excellent photostability for various polymer materials, effectively preventing degradation caused by ultraviolet radiation.

1. The main function of light stabilizer 770 is to prevent UV damage to polymer materials. It can absorb ultraviolet radiation at wavelengths of 290-400nm or quench the energy of excited molecules, effectively reducing the damage of ultraviolet radiation to polymer chains. In addition, it also has the ability to capture free radicals, effectively preventing chain reactions triggered by free radicals through a mechanism similar to hindered phenols, further enhancing the photostability of polymer materials.

2. The light stabilizer 770 has excellent photostability and thermal stability. This means that during the processing and use of polymer materials, even under high temperature or strong light irradiation conditions, the light stabilizer 770 can still remain stable and will not decompose or lose its photostability. This excellent stability enables the light stabilizer 770 to perform excellently in various harsh environments.

3. The light stabilizer 770 also has good compatibility. It can be uniformly dispersed in polymer materials, without exudation, and without adverse reactions with other additives or matrix materials. This enables precise control of the amount of light stabilizer 770 added to polymer materials, thereby achieving the best light stabilization effect.

4. The light stabilizer 770 also has excellent resistance to hydrolysis, water, and other solvent extraction properties. This means that even in humid or solvent containing environments, the light stabilizer 770 can remain stable and will not lose its photostability due to dissolution or hydrolysis. This characteristic makes the application of light stabilizer 770 more reliable in outdoor or humid environments.

5. The light stabilizer 770 has low volatility and low pollution. This means that during the processing and use of polymer materials, the light stabilizer 770 will not evaporate in large quantities into the air and will not cause serious pollution to the environment. This characteristic makes the light stabilizer 770 an environmentally friendly and safe additive.

6. In practical applications, light stabilizer 770 is widely used in polymer materials such as polypropylene, polyethylene, ABS resin, and polyurethane. By adding an appropriate amount of light stabilizer 770, these polymer materials can significantly improve their UV resistance, extend their service life, and maintain good physical and processing properties.

7. The light stabilizer 770 also has the characteristics of being non-toxic or low toxicity. The amount added to polymer materials is usually small and does not release toxic substances during use, so the impact on human health and the environment is relatively small. This has led to the widespread application of light stabilizer 770 in areas that require high safety, such as food packaging and medical devices.

The raw materials for synthesizing Tinuvin 770 mainly include aromatic ketone compounds, amine compounds, and other auxiliary reagents. These raw materials need to be accurately weighed in a certain molar ratio and dried and purified before use to eliminate the influence of moisture and impurities on the synthesis reaction.

React aromatic ketone compounds with bromination reagents (such as bromine or N-bromosuccinimide) in appropriate solvents (such as chloroform or carbon tetrachloride) to generate brominated ketone compounds. This step needs to be carried out at low temperatures and the reaction time must be strictly controlled to prevent excessive bromination. After the reaction is completed, brominated ketone compounds are obtained through filtration, washing, and drying.

Example of chemical equation:

R-CO-R '+Br2 → R-CO-Br+R' - Br

React amine compounds with acylation reagents (such as acetic anhydride or benzoyl chloride) under alkaline conditions to generate acylated amine compounds. This step needs to be carried out under mild conditions to avoid the decomposition of amine compounds. After the reaction is completed, acylated amine compounds are obtained by neutralization, extraction, and drying.

Example of chemical equation:

R-NH2+R'- COCl → R-NH-CO-R'+HCl

Perform condensation reaction between brominated ketone compounds and acylated amine compounds under alkaline conditions to generate precursor compounds of light stabilizer 770. This step requires controlling the reaction temperature and pH value to ensure the smooth progress of the condensation reaction. After the reaction is completed, the precursor compound of light stabilizer 770 is obtained through acidification, extraction, and crystallization.

Example of chemical equation:

R-CO-Br+R-NH-CO-R '→ R-CO-N-CO-R'+HBr

Post treatment of the precursor compound of light stabilizer 770, including washing, drying, and recrystallization, is carried out to remove unreacted raw materials and by-products and improve the purity of the product. This step requires attention to controlling operating conditions to avoid product decomposition or discoloration during the processing.

Final product: acquisition of Tinuvin 770.

Light stabilizer 770, also known as bis (2,2 ', 6,6' - tetramethylpiperidinyl) sebacate. Its photostability is high and suitable for products such as polyethylene, polypropylene, polystyrene, ABS, etc. Especially in polyolefin products, its photostability is 3-4 times that of ultraviolet absorbers and nickel quenchers. Due to its small relative molecular weight, high volatility, poor resistance to movement and extraction, it is suitable for use in thick products. Due to the limitation of high alkalinity, it has an antagonistic effect on halogenated flame retardants, acid dyes, thioesters, as well as acidic resins such as PVC, PC, PMMA, etc. Recently, there has been a trend to use it in combination with high molecular weight HALS, benzotriazole and other ultraviolet absorbers.

(1) 2,2 ', 4,4', 6-pentamethyl-2,3,4,5-tetrahydropyrimidine was prepared by introducing ammonia gas into acetone. Using ammonium chloride as a catalyst, 2,2 ', 4,4', 6-pentamethyl-2,3,4,5-tetrahydropyrimidine reacted in the presence of acetone to produce 2,2 ', 6,6' - tetramethyl-4-oxopyridine. In the presence of catalysts such as skeletal nickel, 2,2 ', 6,6' - tetramethyl-4-oxypiperidine was synthesized by liquid-phase synthesis to obtain 2,2 ', 6,6' - tetramethyl-4-hydroxypiperidine.

(2) Diethyl sebacate is synthesized by esterification of sebacic acid and methanol in the presence of sulfuric acid.

(3) 2,2 ', 6,6' - tetramethyl-4-hydroxypiperidine reacts with dimethyl sebacate to produce the finished product.

(4) A preparation method of hindered amine light stabilizer 770, as follows:

In a 500ml four necked flask equipped with a stirrer, thermometer, and reflux condenser, 0.37mol (75.33g) of sebacic acid, 0.76mol (120.15g) of tetramethylpiperidinol, 3.88g of dioctyltin oxide, and 213.5g of trimethylbenzene were added at room temperature. The mixture was slowly heated to reflux temperature with stirring and kept at 170 ℃ -175 ℃ for 4 hours of reflux water separation reaction. During the reaction process, the reaction progress is determined by analyzing the ratio of mono - and di esters generated by GC, and the reaction is controlled until the end.

After the reaction is complete, cool the solution to 80 ℃, filter to remove the catalyst, and then distill under reduced pressure to remove trimethylbenzene. The remaining material is added with equal weight of petroleum ether and 3.5g of activated carbon, heated to 60 ℃ -70 ℃ and stirred for 1 hour, and then filtered to remove the activated carbon. The remaining petroleum ether solution was cooled to 0-25 ℃, crystallized for 1 hour, filtered and dried to obtain the product. The product was subjected to nuclear magnetic resonance identification, and the results are shown in Figure 1 and Figure 2. It was determined that the product is a hindered amine light stabilizer 770. The melting point of this product is 82 ℃ -84 ℃, with a transmittance of 425nm ≥ 95% and 500nm ≥ 97% (10g/100ml toluene), and a yield of 94% (calculated as sebacic acid).

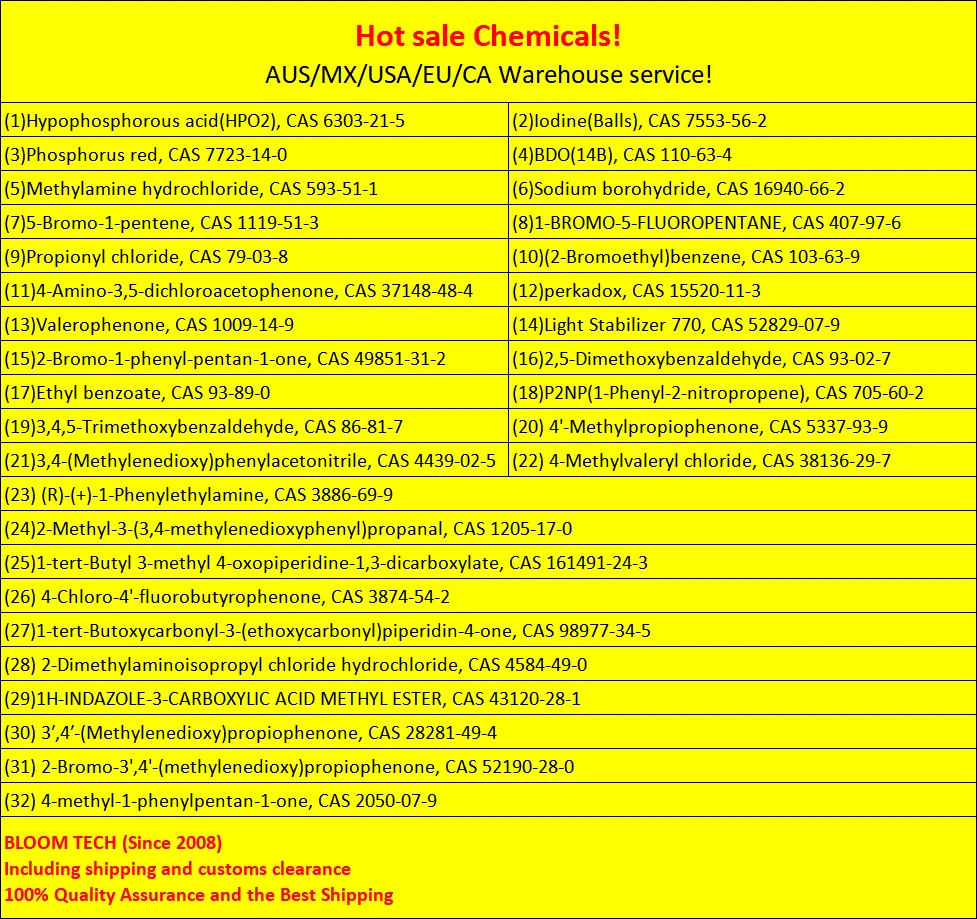

Hot Tags: tinuvin 770 cas 52829-07-9, suppliers, manufacturers, factory, wholesale, buy, price, bulk, for sale, levamisole hydrochloride powder, 4 4 naphthalene 1 2 diylbis 4 1 phenylene bis 2 phenylbenzo h quinazoline , boronic acid B 1 naphthalenyl 2 3 4 5 6 7 8 d7 , 4 4 5 5 Tetramethyl 2 naphtho 1 2 b benzofuran 1 yl 1 3 2 dioxaborolane, CAS 2396743 57 8, paracetamol powder